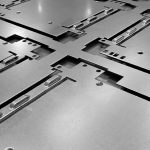

CNC Laser Cutting

Modern Amada X1 4Kw and 3Kw Laser machines with tower facilities to cater for different material types such as Aluminium, stainless steel and mild steels with thicknesses up to 20mm. The X1 Laser has the capability to operate 24 hours / day unmanned and offers tolerances up to +/- 0.01mm.